PRODUCT DESCRIPTION

Flowable Polymer Modified Repair Mortar (PRM™) is a high-performance solution to strengthen and restore damaged concrete structures. It is specially formulated with a low-viscosity polymer base consisting of two polymer components in powder and liquid form.

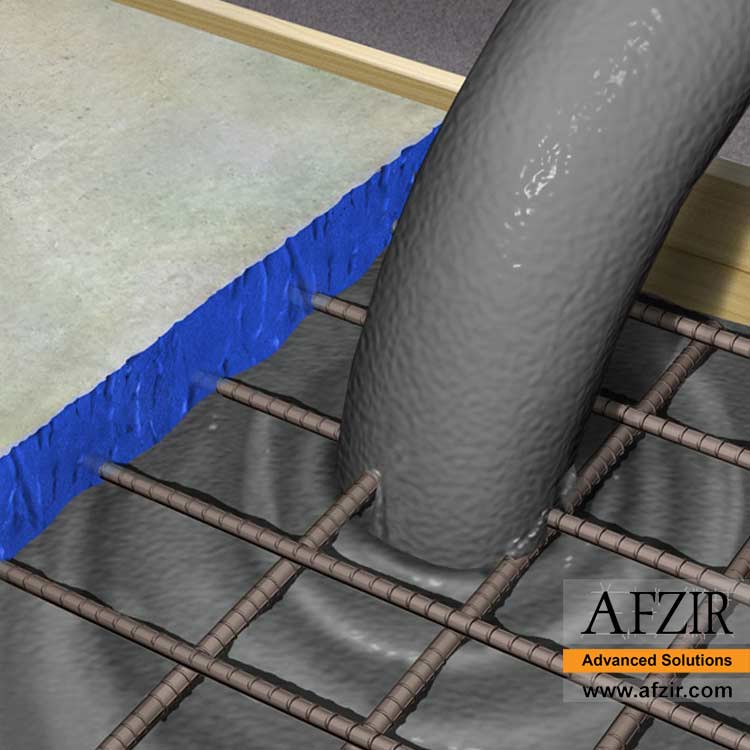

With its exceptional flowability and excellent bonding properties, PRM™ offers an effective and reliable solution for repairing concrete surfaces that are difficult to access or have a high density of reinforcement. Whether it’s cracks, spalls, or other forms of concrete damage, our PRM™ is engineered to provide durable and long-lasting repairs.

Key Features and Benefits:

Flowable and Easy to Apply:

PRM™ has a fluid consistency that allows for effortless application, even in hard-to-reach areas or complex structural components. Its excellent flowability ensures thorough coverage and seamless integration with the existing concrete substrate.

Enhanced Strength and Durability:

By incorporating polymer modifiers, PRM™ significantly enhances the compressive strength, flexural strength, and overall durability of the repaired concrete. It effectively restores the damaged areas’ structural integrity, extending the concrete’s service life.

Excellent Bonding Properties:

PRM™ forms a strong bond with both the repaired area and the existing concrete surface. This ensures optimal adhesion and minimizes the risk of delamination or detachment over time, even under heavy loads or exposure to harsh environmental conditions.

Versatile Application:

PRM™ is suitable for a wide range of concrete repair applications, including repairing concrete columns, beams, slabs, and other structural elements. It can be used in industrial, commercial, and residential settings, offering versatility and adaptability to various project requirements.

Cost-Effective Solution:

By providing a reliable and long-lasting repair solution, PRM™ helps reduce maintenance costs and extends the lifespan of concrete structures. Its ease of application also translates into efficient labor utilization and reduced downtime during the repair process.

Compatibility and Customization:

PRM™ can be tailored to meet specific project requirements, such as adjusting the flowability or setting time based on temperature conditions and other factors. It is compatible with various concrete surfaces and can be used with other repair materials or systems.

When it comes to restoring damaged concrete, our Flowable Polymer Modified Repair Mortar (PRM™) offers a high-quality solution that ensures exceptional performance, longevity, and cost-effectiveness. Trust our PRM™ to revitalize your concrete structures and provide durable repairs that withstand the test of time.

The price of Flowable Polymer Modified Repair Mortar (PRM™)

It can be determined by considering several factors. Here are some key aspects that can influence the pricing:

Market Conditions:

The overall market demand and supply dynamics for repair mortars, including PRM™, can impact the price. Factors such as competition, availability of similar products, and market trends can affect pricing.

Raw Materials:

The cost of the raw materials used in manufacturing PRM™, such as polymers, cement, additives, and fillers, can play a significant role in determining the price. Fluctuations in the prices of these materials can affect the overall cost of production and, subsequently, the product price.

Manufacturing Process:

The complexity and efficiency of the manufacturing process can influence the price. If PRM™ requires advanced technologies, specialized equipment, or extensive quality control measures during production, it may affect the final price.

Product Quality and Performance:

PRM™ with superior quality and performance attributes, such as high strength, durability, and adherence to industry standards, may be priced higher due to its added value to customers.

Packaging and Delivery:

Packaging materials and transportation costs can contribute to the final price. The type of packaging used, logistics expenses, and any additional services provided, such as product delivery or technical support, may affect the overall cost.

Brand and Reputation:

Established brands with a strong reputation for providing reliable and high-quality repair mortars may price their products at a premium due to customer trust and brand recognition.

Features

- Low viscosity repair mortar

- High adhesion and durability

- Easy and convenient implementation of repair mortar when the density of reinforcement is high

- The possibility of applying mortar with a thickness of 200 mm

- Non-separation of mortar granulation

- Repair mortar without shrinkage

- Absence of chlorine and harmful chemicals in mortar composition

- Low permeability to water and chloride

- The possibility of mortar execution as a shot

- High resistance to melting or freezing

Applications

- Afzir Reinforcement Company recommends PRM™200 mortar for spreading or pumping concrete behind the mold or inside the repair area.

Packaging

- First component: 25 kg bag

- Second component: 5 liters of liquid

Colour

- Gray liquid (after mixing)

technical specifications

|

Initial setting time |

1.5-3 hours |

| final setting time |

4-5 hours |

| compressive strength |

34.5MPa |

| Tensile strength |

4.5MPa |

|

flexural strength |

6.2MPa |

|

Bond strength |

10MPa |

For engineers seeking an effective solution to prevent corrosion, cracking, and shrinkage in large volumes of concrete structures, we highly recommend the use of this fluid mortar. Its versatile application extends to various areas, including:

Columns, beams, and piers:

Apply the fluid mortar to reinforce and protect these critical structural elements, enhancing their strength and durability.

Concrete bridges and marine structures:

Utilize the fluid mortar to safeguard against the corrosive effects of water and provide long-term protection in challenging marine environments.

Sewage treatment plants and concrete facilities:

Apply the mortar to combat the aggressive chemical and moisture conditions found in these environments, ensuring the longevity of the structures.

Industrial structure floors:

Enhance the performance and longevity of industrial floors by applying fluid mortar, which provides excellent resistance against heavy loads, abrasion, and impact.

Horizontal surfaces, both internal and external: Achieve smooth and durable concrete surfaces by utilizing the fluid mortar for horizontal alignments, guaranteeing uniformity and strength.

Moreover, this fluid mortar is particularly suitable for areas with dense reinforcement, where mechanical spraying becomes challenging. Its flowability ensures comprehensive coverage and seamless integration, even in hard-to-reach areas.

It is important to note that the 28-day compressive strength of the concrete, achieved at a temperature of 23 degrees Celsius, meets the required standards, further reinforcing the reliability and performance of this fluid mortar.

By incorporating this fluid mortar into your concrete projects, engineers can effectively mitigate corrosion, cracking, and shrinkage issues, ensuring the long-term durability and structural integrity of the concrete structures.

Contractors are strongly advised to utilize this specialized repair mortar for addressing challenging repair needs in concrete buildings, particularly in areas that are difficult to access. This repair mortar is highly effective in significantly reducing and minimizing concrete cracking and shrinkage. It can be applied to any concrete layer, providing reliable repairs for up to 200 mm thicknesses.

Mixing the mortar with the liquid component forms a fluid consistency that facilitates ease of application. This fluid mortar exhibits exceptional resistance when used for repairs in large volumes and extensive areas. Additionally, it is crucial to note that this mortar does not react with carbon and sulfate, ensuring compatibility with a wide range of concrete compositions.

By incorporating this flowable polymer modified repair mortar into construction and repair projects, contractors can confidently address the challenges posed by hard-to-access components of concrete buildings. The mortar’s ability to effectively minimize cracking and shrinkage, along with its versatility in application thickness and compatibility with different concrete compositions, makes it an ideal choice for ensuring durable and long-lasting repairs.

Surface Preparation:

To achieve optimal adhesion, it is essential to thoroughly clean and smoothen the desired surface. Before applying PRM™ 200, ensure the substrate is completely dry and free from dust, oil, grease, paint, and any surface imperfections. The substrate should be moistened 24 hours prior to mortar application.

Mixing:

Combine the powder (part A) and liquid (part B) components in a mechanical mixer at a low speed. Mix until a homogeneous and bubble-free composition is obtained. The mixing process should be completed within 60 minutes, and the ambient temperature should be maintained at approximately 20 degrees Celsius. Avoid adding any additional mortar or water to the prepared liquid mortar.

Cleanup:

Clean tools and mixers immediately after use with water. If any materials have dried or hardened, mechanical methods may be required for removal.

By following these surface preparation, mixing, and cleanup guidelines, contractors can ensure the optimal adhesion, homogeneity, and durability of the PRM™ 200 mortar application.

Safety tips for working with polymer mortar with low viscosity:

-

Use a mask to protect against suspended particles created during the application of the polymer mortar.

-

Wear gloves to prevent skin allergies or irritation.

-

Use safety glasses to protect your eyes from any potential irritation or contact with the material.

-

When working in environments exposed to chemicals, use appropriate protective clothing, gloves, and goggles.

-

Ensure the work area is well-ventilated to minimize exposure to airborne particles.

In case of skin contact, promptly wash the affected area with soap and water. -

If the product comes into contact with your eyes, immediately flush them with plenty of water.

-

If you experience any breathing difficulties during use, seek medical advice from a doctor.

-

Storage Conditions for Low Viscosity Polymer Mortar:

The PRM™ 200 should be stored under specific conditions to maintain its quality:

Shelf Life:

The product can be used for up to 12 months from the production date, provided it is stored correctly.

Packaging:

Store the product in its original packaging, which is designed for optimal protection.

Storage Location:

Place the packaged material on protective pallets in a dry area, away from direct sunlight.

By adhering to these quality control measures and safety guidelines, contractors can ensure the safe handling, storage, and usage of PRM™ 200, maintaining its effectiveness and integrity throughout its shelf life.

technical documents

Photo Gallery

Technical documentation request

Be the first to review “Flowable Polymer Modified Repair Mortar”