PRODUCT DESCRIPTION

Introducing Cosmetic Leveling Repair Mortar (LRM™), a high-performance solution for achieving flawless concrete surfaces. LRM™ is a single-component leveling cosmetic mortar specially designed to address shrinkage issues during the final stages of concrete repair.

Crafted with precision, LRM™ combines top-grade cement, meticulously graded sand, advanced polymer additives, and specialized fibers. This unique formulation ensures exceptional workability, superior bonding, and minimal shrinkage, resulting in a smooth and seamless finish.

LRM™ is effortless to use. Simply mix it with water, and a complete mortar is ready to tackle any repair or leveling task on concrete surfaces. Whether you’re fixing cracks, filling voids, or smoothing out imperfections, LRM™ delivers exceptional results every time.

The benefits of LRM™ extend beyond its remarkable performance. Its carefully selected components enhance durability, providing long-lasting results that withstand the test of time. Additionally, LRM™ offers excellent adhesion properties, ensuring a strong bond to the existing concrete substrate.

Ideal for both professional contractors and DIY enthusiasts, LRM™ simplifies the concrete repair process while achieving outstanding cosmetic results. Whether you’re working on driveways, crosswalks, patios, or other concrete surfaces, LRM™ is the go-to solution for achieving a flawless, level finish.

Trust Cosmetic Leveling Repair Mortar (LRM™) to transform your concrete repair projects into seamless works of art, leaving behind a surface that’s not only structurally sound but also visually appealing. Experience the difference of LRM™ and elevate your concrete repairs to new heights of excellence.

Features

- Low shrinkage

- Does not contain chloride

- Very high adhesion and flexibility

- Low permeability to moisture and chemicals

- Resistant to thawing-freezing cycle

- Resistant to environmental corrosion factors

- High abrasion resistance

Applications

- Filling cracks and holes and unevenness created on the surfaces and elements of damaged concrete and masonry structures

- Repair of fracture of concrete bridge deck and prefabricated concrete parts

- Repair and restoration of tanks

- Filling the pores of surfaces and walls

Packaging

- Powder bags

Colour

- Grey

technical specifications

|

Chemical base |

cement |

|

Pot life |

30-45 minutes |

| Initial set |

45-75 minutes |

| Final set |

60-120 minutes |

| density |

1.8 g/cm3 |

|

compressive strength (1 days) |

25 N/mm2 |

| Adhesion to concrete (28 days) |

2.8 N/mm2 |

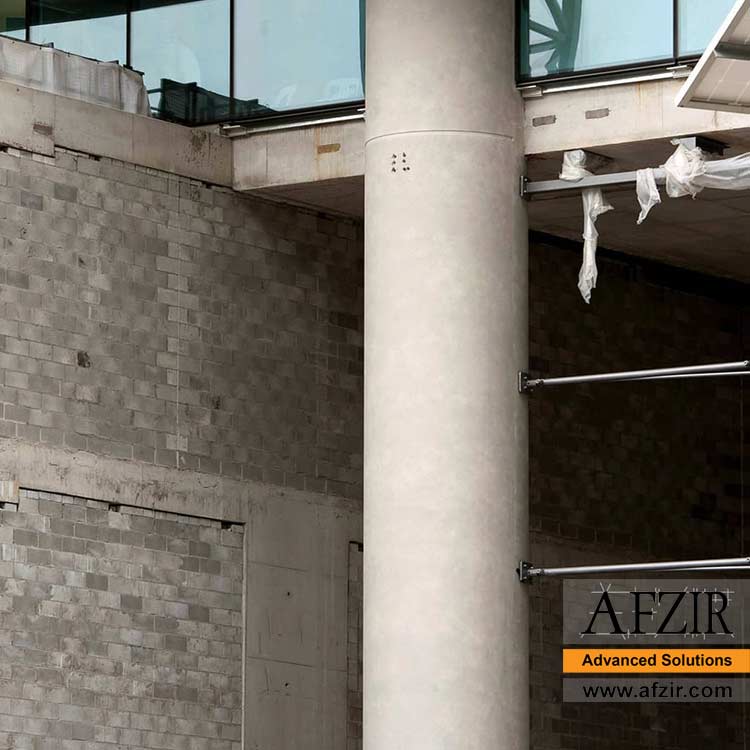

Cosmetic Leveling Repair Mortar (LRM™) is an ideal repair layer for damaged or honeycombed concrete surfaces, providing a consistent appearance to the desired finish. Supervisors and designers have recognized the remarkable capabilities of LRM™ in effectively eliminating cracks, honeycombing, and surface roughness on exposed concrete facades. LRM™ is particularly suitable for projects where preserving the original concrete shape is crucial, offering both functional and cost-effective benefits.

Contractors will find this product highly convenient and efficient to work with. This modified polymer-based solution requires only clean and potable water for preparing the mortar, making the mixing process hassle-free and straightforward. The bonds formed by this mortar exhibit exceptional strength, making it an ideal choice for cosmetic repair and surface smoothing of concrete.

LRM™ mortar finds extensive application in building facades and areas where aesthetics is crucial. It effectively fills voids and seams in prefabricated concrete walls, enhancing their visual appeal. Moreover, contractors can rely on LRM™ mortar as a reliable underlayment for various epoxy and polyurethane paints, providing a seamless and durable base.

With its user-friendly nature and versatility, LRM™ mortar simplifies the work of contractors, allowing for efficient and high-quality concrete surface repairs and enhancements. Experience the convenience and reliability of LRM™ for your projects and elevate the quality of your craft.

Preparation Instructions:

To ensure proper preparation of the mortar with the desired thickness, it is important to begin by dampening a thin layer that will come into direct contact with the LRM™ mortar. When using this product to fill cavities, apply it directly into the pores using a trowel. Prior to application, ensure that the concrete surface is thoroughly cleaned and free from oil, grease, excess water, additional substances, dust, and any damaged concrete. Moistening the desired surface will enhance adhesion.

Mixing Procedure:

Gradually add the dry ingredients into a container while mixing with some clean water. Alternatively, use a mixer at a low speed to achieve a homogeneous and uniform gray mortar.

Surface Cleaning:

Clean tools and mixers immediately after use with water. It is important to note that dried and leftover materials can only be removed through mechanical methods or by using specialized brushes.

Safety Precautions:

- Wear a mask to protect against airborne particles that may be generated.

- Use gloves to prevent skin allergies and irritation.

- Wear safety glasses to protect your eyes from potential irritation.

- Wear appropriate clothing, gloves, and safety glasses when working in environments exposed to chemicals.

- Ensure the work area is airy to promote air circulation.

First Aid:

- In the event of skin contact, wash the affected area thoroughly with soap and water.

- If the product comes into contact with the eyes, rinse immediately with plenty of water and seek medical attention if necessary.

- If breathing difficulties occur during use, seek medical assistance.

Maintenance:

- The product can be used for up to 12 months after production when stored in unopened, specially sealed packages.

- Store the packets in a dry place at ambient temperature, away from direct sunlight and moisture.

technical documents

Photo Gallery

Technical documentation request

Be the first to review “Cosmetic Leveling Repair Mortar”