PRODUCT DESCRIPTION

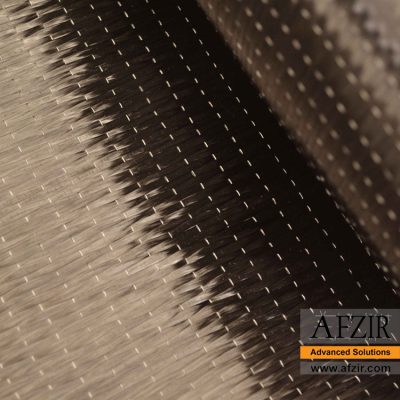

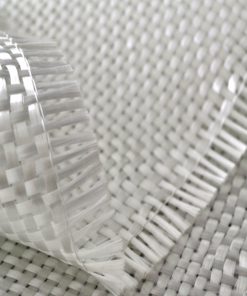

UD Carbon Wrap (UCWTM) is a non-woven carbon reinforcement with all fibers aligned in a single, parallel direction (0°). It is a crucial member of the advanced fiber family. It offers remarkable properties, including high strength (7 to 10 times that of steel, depending on the fiber type), low density (approximately 70% of aluminum), excellent electrical conductivity, and superior texture and fabric production capabilities. These attributes enable the creation of lightweight, strong composites with exceptional heat resistance, setting them apart from other engineering materials. Carbon fiber is widely utilized in various applications due to its outstanding mechanical, thermal, and electrical properties, with a significant portion of its global production dedicated to composites.

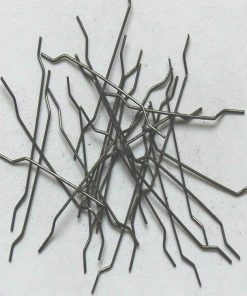

Afzir Company provides a comprehensive range of UD Carbon Wrap options to suit specific project requirements. Carbon fiber is available in specifications such as 1K, 3K, 6K, 12K, 24K, chopped fiber, and more, catering to diverse industries, including aerospace, sports goods, medical equipment, infrastructure, and boat building. Its primary application lies in reinforcing and retrofitting structures and their components, such as beams, columns, bridges, pipes, silos, etc.

Advantages of Unidirectional Carbon Wrap (UD Carbon Wrap):

- Lightweight: UD Carbon Wrap is 1/4 the density of steel, resulting in lighter structures.

- High Strength: Just 1mm of the fabric reinforces without adding weight or size.

- High Flexibility: The material can closely cover structures with unique shapes and operate in narrow spaces.

- Efficiently designed: Easy to use without requiring large machines, tools, or wet construction.

- Versatility: Suitable for reinforcing various concrete, masonry, and wood structures.

- Durability: Resistant to corrosion, acids, alkalis, and salt in harsh environments.

- Environmentally friendly: The fabric is non-toxic, tasteless, and pollution free.

What is the price of unidirectional carbon fiber?

The price of unidirectional carbon fiber varies depending on various factors, such as the type of carbon fiber, the specific application, and the quantity required. The global carbon fiber market is projected to experience significant growth, with an estimated increase from $2.33 billion in 2021 to $4.08 billion in 2028, achieving a compound annual growth rate (CAGR) of 8.3% during the forecast period of 2021-2028. This growth can be attributed to advancements in the automotive, aerospace, defense, and wind energy industries, where lightweight materials are in high demand due to regulations concerning carbon emissions and the need for fuel efficiency.

At Afzir Company, we take pride in offering guidance for purchasing carbon fabric and UD Carbon Wrap, ensuring quality products at reasonable prices. Our team of experts at Afzir can provide information regarding carbon fabric pricing and the appropriate quantity required for your specific project. Feel free to contact us for further assistance.

When contacting our team, please provide specific details about your project, such as the desired quantity of carbon fabric and any additional requirements or specifications. This will enable us to provide accurate pricing information tailored to your needs. We are committed to delivering excellent customer service and ensuring your satisfaction throughout purchasing.

-

Key Features

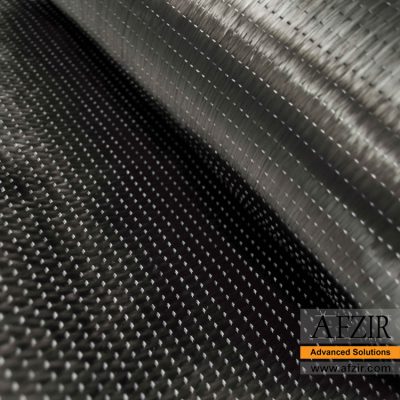

- Dense uniform fabric, good softness

- Easy to shape, good structure

- Light weight, high strength, high modulus, anti-corrosion, and conductive.

- Minimal change to structure’s shape, weight or appearance

- Compatible with a variety of resins and adhesives including epoxy resins

- Thermal compatibility

- Flexible wrap conforms to any shape

- Excellent fatigue behavior

- Faster repair than alternative methods

- Welding and heavy equipment not needed

- Minimal disruption and noise during preparation or installation

- Low total cost

- Environmental-friendly

Applications

- Seismic reinforcement and improvement of various structures

- Reconstruction of old and dilapidated buildings

- Reinforcement of columns, beams, walls, roofs and concrete foundations

- Increase the load-bearing capacity of building elements

- Change the structural function

- Remit mistakes in design and construction

- Manufacture of CFRP composite products

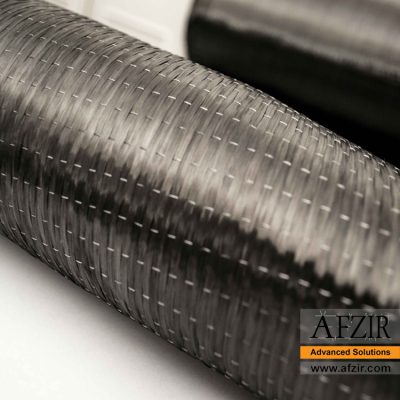

Packaging

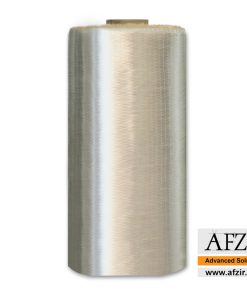

- Afzir company will provide you a wide range of carbon fiber unidirectional fabric material (UD Carbon Wrap) with the Thicknesses of 0.09-0.17 and widths of 500 and 1000 mm.

Colour

- Black

technical specifications

|

Arial Weight |

160-300 gr/m² |

|

Fabric Thickness |

0.09-0.17 mm |

|

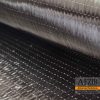

Weave Pattern |

UD |

|

Primary Fiber Direction |

0° |

|

Width(mm) |

50-100 mm |

|

color |

black |

|

Comparison of properties of UD Carbon Wrap with conventional construction steel |

||

|

parameter |

UD fiber |

steel |

|

Tensile Strength |

4900MPa | 360MPa |

|

Tensile Modulus |

230GPa |

200GPa |

|

Density |

1800Kg/m³ |

7850Kg/m³ |

|

Corrosion resistance |

Yes |

No |

| Acid resistance | Yes |

No |

In general, the reinforcement of structures is done in order to increase the bearing capacity of the building, improve the defects caused by corrosion and erosion, increase the ductility of the structure, the need to change the use of the structure and compensate for design and execution errors.

UD Carbon Wrap is corrosion resistant and has high tensile strength, and its low weight, which is one of the goals of retrofitting, has led to an increasing use of them in seismic retrofitting and improvement projects.

In order to perform reinforcement in projects, it is necessary to thoroughly examine the current condition of the structure, such as the current bearing capacity of the elements, defects, the calculation files of the structure, and the existing documents and drawings of the structure.

General principles of unidirectional carbon fiber reinforcement system design

General principles and general design method are based on the limit state to provide an acceptable level of performance and safety, and due to less knowledge of FRP composites than other available materials such as concrete, it is necessary to apply strength reduction coefficients. So that the design reliability coefficient is more than 3.5. It is also necessary to measure the properties of existing materials such as compressive strength, modulus of elasticity and… by tests such as core drilling and compressive strength testing and ultrasonic testing.

Types of behavior of unidirectional carbon fibers (UD Carbon Wrap)

Tensile behavior of UD Carbon Wrap

Under direct tensile loading, the carbon fibers have no plastic behavior before rupture. The tensile behavior of materials is characterized by an elastic linear stress-strain relationship until sudden failure occurs. Tensile strength and hardness of materials depend on several factors. Since fibers play an essential role in bearing in FRP composite, the type of fibers, orientation and also their amount of them play the most important role in tensile properties.

Compressive behavior of components reinforced with UD Carbon Wrap

UD Carbon Wrap that acts as an outer covering should not be used as a compression reinforcement. However, in columns, due to the confinement behavior of compressive resistant fibers and the capacity of the column increases indirectly.

Evaluation and acceptance

To evaluate the FRP system, the direction of the fibers, the presence of layer separation and adhesion to the surface, the location of the layers and… and Also, the compliance or non-compliance with the design drawings should be checked by the supervisory body, which we will refer to some of the cases and tasks of the supervisory body.

To use unidirectional carbon fiber in projects, these materials must be controlled based on laboratory information about these materials. Laboratory information is provided by the supplier company.

After installing and obtaining the strength of CFRP composites, the adhesive tensile test (Pull-Off test) is performed on the core samples and the adhesive resistance must be more than 1.4 MPa to observe the phenomenon of separation and rupture in concrete. If the strength is less than the specified value or the FRP system separates from the concrete, it indicates that the system is defective and the carbon fiber cannot provide the expected performance.

To evaluate and approve the installed fibers, other things should be considered, some of which we will mention:

Occurrence of separation phenomenon

- For the placement of the layers, the direction is very important and the presence of deflection even by 5 degrees from the specified direction can have a great impact on reducing resistance.

- Thickness after curing with resin

- The length of the fiber splice

Rehabilitation goals

In general, the purpose of reinforcement is to increase the tolerance of the structure against various forces, especially earthquakes. Of course, the purpose of reinforcement is not always to increase the resistance of the structure to earthquakes and can have other causes such as change of use of a building and reduced the quality of materials. Building retrofitting can be considered in two types of buildings:

- Existing and in use buildings

- Earthquake-damaged buildings

Since the demolition and replacement of existing buildings with the new ones is very costly and time-consuming, so the importance of retrofitting buildings is increasing day by day.

Requirements for retrofitting in the building

In the following, we refer to the cases that in case of any of them, we need to present a plan and implement retrofitting in the building:

existing damage in old building

One of the most common cases in buildings is damage and defects during the use of the building. These damages can be seen in different forms in buildings. honeycombing, abnormal cracks and corrosion of rebars in beams, columns and roofs can be considered as common failures in concrete buildings, although many of these cases are not easily detected and Need to perform various methods of concrete testing, including corrugation, rebar scanning and …

Executive errors

Mistakes that occur during the implementation phase need to be investigated by retrofitting experts. These errors can occur in many different ways in different buildings, such as weakness in concrete test specimens, inconsistency of concrete design strength with existing strength, beam and column buckling, honeycombing, and so on.

Change of use of a building

These days, Changes in the use of buildings are common and are among the cases in which the building must be thoroughly examined by experts before doing so. Changes in the use of the building create new forces in the members of the building for which the building is not designed, and their emergence may cause severe breakage and damage to the load-bearing members such as beams, columns and… In these cases, it is necessary for the experienced consulting engineer to fully evaluate the existing structure and perform the feasibility of change of use in order to finally provide a plan with high accuracy and complete details.

detection of defects in a proper time and choosing the right solution will save a lot of building costs. Since choosing an inappropriate method of strengthening, repairing or retrofitting a structure can even make matters worse, it is necessary to seek the help of experienced and expert people in this field.

As there are various retrofitting solutions, employers also have different options for it and they must choose one of these methods to implement in their projects. Reinforcement using unidirectional carbon fiber is a method that is becoming more and more widely used. But what are the most important reasons for the pervasiveness of unidirectional carbon fiber retrofitting?

high resistance, low weight, Lack of conductivity of electricity, reduction in costs and…

There are also problems that other common methods of retrofitting, such as steel and concrete jackets, create for the building, such as weight gain, changes in architecture, disruption of long-term use of buildings, rising costs, and so on. The possibility of recurring problems such as corrosion and rust all add to the benefits of reinforcement using unidirectional carbon fiber.

The details of the implementation of UD Carbon Wrap depend on the geometry of the structure, the smoothness of the substrate and so on, and It is necessary for the contractor to use FRP materials in accordance with the specifications described by the consulting engineer, such as type of fibers, type of resin, number of layers, method of execution and… in performing reinforcement operations.

Steps of implementing UD Carbon Wrap

Carbon fiber reinforcement systems should be implemented according to the following steps and carefully to achieve the desired quality.

Concrete repair and substructure preparation

It is necessary to eliminate all the defects in the main concrete and the underlying concrete, which may affect the integrity of the CFRP composite, before applying the fibers, and also in cases where there is a possibility of corrosion and rust of the rebars in the concrete, Corrosion and sediments should be cleaned and damaged.

Mixing resins

Mixing of resins should be done according to the procedure recommended by the manufacturer in accordance with the technical specifications of the project. All resin components must be mixed at a suitable temperature and in sufficient quantity until the material

A variety of methods for installing UD Carbon Wrap

After preparing the substrate, it is time to install FRP fibers, which have different methods and the installation method must be specified by the consultant. Here are some ways to install FRP fibers:

UD Carbon Wrap wet gluing system

In this installation method, the fiber system is installed by hand without corrosion or dry resin. The fibers can be fertilized and impregnated in a separate process with the help of a device impregnated with resin materials and then installed on the concrete surface.

Pre-impregnated fiber system

unidirectional pre-impregnated systems are first impregnated with resin at the factory, but the resin is not cured. These fibers are bonded to surfaces with or without additional resin and cured on site.

Failure to comply with any of the above and other cases expressed by the consultant and the manufacturer will cause a weakness in the bearing of the system and in some cases the fibers will be separated from the surface. Fibers will prevent:

- Avoid sticking UD Carbon Wrap on the inner surface of the corners as much as possible and observe sufficient development length

- overlap should be applied to the patched areas

After the implementation of the FRP system, it is necessary to implement quality assurance and control programs and programs by the quality control unit (QC). Quality control should be done through a series of required inspections and tests.

Quality control inspectors should be fully familiar with the FRP system and how to implement and install it, and during the installation of the unidirectional carbon fiber system should conduct daily inspections, which should include the following:

- Ambient temperature, relative wetness and weather conditions

- The dryness of the surfaces

- Surface preparation methods

- Observe the resin curing process

- The position and size of any layer separation or the presence of air bubbles

The quality control unit should also periodically inspect and evaluate the implemented CFRP composite.

Types of FRP system evaluation methods

General inspections

With general visual inspections, any changes in color, fiber separation, cracking, etc. are examined, and the presence of any of these factors indicates a weakness in the system and improper execution. The nature of FRP composite materials is such that they should never or very rarely be repaired during operation, so surfaces covered with FRP materials should be generally monitored and inspected.

One of the common failures in FRP systems is the separation of concrete composite materials, which is a very dangerous failure that if it occurs, the FRP system is practically inefficient. Therefore, the separation of concrete composite materials should be evaluated. The best way to diagnose this condition is to perform a pull-off test, which should be done at regular intervals according to the regulations. Make a correction for it. If minor damage to the composite material is detected, it can be repaired by methods such as resin injection with caution so that the material is not further damaged. If general and more significant damage, such as scaling or separation of layers, occurs on a large scale, adhesives and composites may need to be removed. Defective materials are removed from the concrete surface on a large enough surface and the cleaned part is re-coated with new materials.

Long-term monitoring and inspection

According to the monitoring and inspection system, like all structural members, the reinforcement system with UD Carbon Wrap must be monitored and inspected. Such measures for bridges are usually carried out once a year in general and every six years in detail, but regular inspections of buildings are rarely carried out. Building quality control engineers need to justify regular monitoring and inspection of reinforced members, and CFRP composite reinforced buildings should be regularly monitored and inspected for reinforced members.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

What are some of the characteristics of UD Carbon Wrap that have increased its production and use?

Features such as very high mechanical strength, low weight, high impact resistance and wear, high corrosion resistance due to chemical reactions and acidic environments, heat resistance, ease of installation, etc. lead to increased demand for single carbon fibers Direction and consequently its production has increased.

What are the weights of UD Carbon Wraps?

UD Carbon Wraps are available in 160, 200, 240 and 300 g weights.

What are the methods of installing unidirectional carbon fibers?

(A) Wet UD Carbon Wrap bonding system (b) Fiber pre-impregnated system

What can be made using carbon fiber and composite?

Bicycle frames, aircraft wings, car drive shafts, tubes, containers, impeller blades, self-made parts made of carbon fiber composites can reduce the weight of a passenger car by up to 50% without compromising vehicle performance or occupant safety. In addition, it improves fuel efficiency by approximately 35%.

What is the unit price of UD Carbon Wrap surface?

Because carbon fiber is a polymer and refinery product, and since these products have reached mass production in the country, these products can be purchased at reasonable prices from various companies. For information on the daily price of the products, you can contact our experts at Afzir Company.

What is a CFRP system and what is it used for

Carbon fibers, after saturation and complete impregnation with FRP resins and adhesives (epoxy resins, etc.) form a CFRP system and are used to reinforcing and increase the strength and efficiency of structural elements against various forces

Why are UD Carbon Wraps known by this name?

UD Carbon Wraps are woven using carbon fiber yarn. These fabrics are named based on the type of texture and the direction of the texture. For this purpose, fibrous fabrics made from carbon fiber yarns woven in one direction are called unidirectional carbon fiber fabrics.

What is the use of unidirectional carbon fibers?

Unidirectional carbon fibers are used in various industries and fields, including structural reinforcement, composite, aerospace, defense, automotive and other industries.

In what applications is UD Carbon Wrap preferable to bidirectional carbon fiber?

UD Carbon Wraps are more preferred than bidirectional carbon fibers in applications where the reinforcement of an element in a particular direction or direction is universally intended.

Which resins are compatible with UD Carbon Wrap?

There are three types of carbon fiber compatible resins: epoxy resin, vinyl ester resin and polyester resin. But the best performance and high adhesion are provided by epoxy resin and vinyl ester resin to unidirectional carbon fibers.

Be the first to review “Unidirectional Carbon Wrap”