PRODUCT DESCRIPTION

Concrete Polymer Repair Mortar:Enhancing Durability and Strength

Concrete is renowned for its strength and durability, enabling the construction of heavy and high-rise structures. However, even these materials are not resistant to defects and require periodic repairs and reconstruction throughout their lifespan. Effective strategies during the repair and rebuilding of concrete are crucial, as they can mean the difference between successful restoration and costly failures.

The Polymer Concrete Repair Mortar (PRMTM400) from Afzir Company is part of a range of repair mortars designed to address concrete repairs. This polymer concrete mortar is a potent inhibitor against erosion and corrosion, offering versatile usage in horizontal and vertical structures.

With its modified composition, polymer concrete mortar enhances the capabilities of concrete in various construction structures such as industrial warehouses, parking lots, and roads, improving their resistance to heavy loads and abrasions.

Types of Concrete Damage

Concrete damage can occur due to various factors, including execution errors and environmental conditions. Execution-related damage includes issues like honeycombing, inadequate cleaning of formwork, improper formwork execution leading to joint formation, and displacement of molds. Damage arising from environmental conditions and operation can result from exposure to corrosive substances, loss of concrete cover, and the subsequent appearance of rebar, necessitating the use of concrete repair materials.

Identifying the different types of concrete damage often requires concrete testing, as they may not be visible to the naked eye.

Methods for Repairing Damaged Concrete

The most suitable method for repairing concrete in a structure depends on the required thickness of the repair mortar layer. Two approaches exist for repairing mortar layers less than 5 cm thick. The first method involves manually spraying the prepared concrete surface with mortar or using a specialized spraying device (shotcrete). The second method employs a spatula to repair the damaged area.

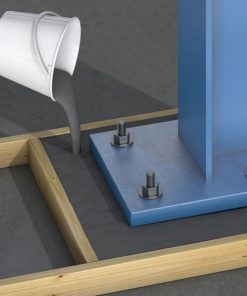

For repair mortar layers thicker than 5 cm, the process involves preparing the concrete surface, creating formwork, and subsequently applying the repair mortar to the concrete surface.

In addition to considering the required thickness of the repair mortar layer, the execution conditions and the location of the repair (e.g., beam, roof, column) play a significant role in selecting the appropriate execution method.

Factors Affecting Concrete Structure Integrity

Concrete repair and reinforcement are integral parts of a comprehensive construction process, requiring meticulous planning and strategy. Assessing project conditions, understanding the type and cause of concrete failure, and gathering information about the structure’s usage conditions are essential for formulating a successful repair plan. Failures such as cracking, scaling, leakage, wear, subsidence, deflection, and disintegration can lead to concrete failure and structural damage. A sound technical understanding of concrete failure types at the project level is necessary to use polymer concrete mortar or any other repair method effectively. This enables the creation of a successful repair strategy and selecting the appropriate concrete repair method based on the identified causes of failure.

The Market for Polymer Concrete Mortar

The global market for concrete repair mortar production and usage is continuously expanding, with thermal polymer mortar witnessing significant growth in this field. In 2012, the market value of concrete repair mortars was estimated at $2 billion, and it is projected to reach $3.6 billion by 2027. The market’s growth rate for various types of concrete repair mortars exceeds 7% annually.

Several factors contribute to the development of the market, including population growth, increased infrastructure demands, and the necessity to extend the lifespan of existing buildings. As concrete has been utilized in construction for nearly a century, numerous deteriorating structures require major repairs. The global demand for ready-mixed concrete repair mortars, particularly polymer-based options, drives market visibility and inevitably affects the price of concrete repair mortar. Afzir Company, a prominent player in the concrete repair mortar industry, is actively engaged in selling high-quality concrete repair mortars. Customers and contractors can easily inquire about the required materials and prices for various types of concrete mortar by contacting the company’s experts with a phone call.

Key Features

- Fast setting and good adhesion to the substrate surface

- High compressive and flexural strength

- Mortar without shrinkage to prevent surface cracks

- Suitable slump with execution method

- High viscosity concrete repair mortar

- Maximum resistance in the shortest time

- Resistant to environmental conditions such as corrosive materials and freezing cycles

- Having a coefficient of thermal expansion close to concrete to prevent the separation of the repair mortar from the substrate concrete due to expansion due to heat change

- Full compatibility with all types of concrete

Applications

- Using 400 ™ PRM polymer concrete repair mortar, we are able to repair all kinds of damage related to concrete members, including damage caused by execution and operation, and damage caused by destructive environmental conditions.

Packaging

- In two components: powder (25 kg) and polymer liquid (5 liters)

Colour

- grey paste (after mixing)

technical specifications

| Compressive strength |

28.5 MPa |

| tensile strength |

5.51 MPa |

| flexural strength |

8.27 MPa |

Familiarize yourself with the product: Understand its properties and application guidelines.

Conduct proper surface preparation: Ensure the substrate is clean and contaminant-free.

Follow mixing instructions: Adhere to recommended ratios and achieve a uniform mixture.

Use appropriate application techniques: Select the suitable method for the repair requirements.

Consider ambient conditions: Account for temperature, humidity, and wind during application.

Ensure proper curing: Follow the manufacturer’s instructions for the curing process.

Monitor and inspect the repair: Regularly check for any issues or concerns.

Document the repair process: Keep records of materials, techniques, and conditions used.

These recommendations will help engineers effectively work with PRMTM 400 and achieve successful concrete repairs.

- Understand the product: Thoroughly understand PRMTM 400’s properties and limitations.

- Collaborate with engineers and architects: Communicate closely with project professionals to clarify repair objectives.

- Proper surface preparation: Clean and prepare the repair surface according to the manufacturer’s guidelines.

- Follow mixing instructions: Adhere to recommended ratios and achieve a consistent mixture.

- Train and educate workers: Provide training on proper application techniques and equipment use.

- Adhere to safety protocols: Ensure compliance with safety regulations and provide necessary PPE.

- Monitor environmental conditions: Consider temperature, humidity, and wind during application.

- Use proper application techniques: Apply PRM™ 400 using recommended methods for uniform coverage.

- Allow adequate curing time: Follow the manufacturer’s instructions.

- Conduct quality control checks: Regularly inspect repaired areas for defects and address issues promptly.

- Maintain records: Document project details, including materials, ratios, techniques, and curing methods.

The process of repairing damaged concrete involves the following steps:

Removal of damaged concrete:

Begin by removing the compromised or deteriorated concrete sections to prepare the surface for repair mortar application.

Dust removal:

Use air pressure or wash the surface with water to eliminate any dust or debris. This step ensures optimal bonding between the concrete repair mortar and the existing concrete.

Application of concrete repair mortar:

Apply the concrete restorative mortar onto the prepared surface using a suitable method. This can involve techniques such as spraying, troweling, or other recommended application methods.

Processing of concrete repair mortar:

After applying the repair mortar, carefully follow the recommended processing guidelines. This may involve smoothing the surface, ensuring proper curing conditions, and any other specific instructions provided by the manufacturer.

By following these steps diligently, you can effectively repair damaged concrete and restore its structural integrity.

Pre-Application Inspection:

- Conduct a visual inspection of the repair area.

- Address any existing issues before applying PRM™ 400.

Material Inspection:

- Check PRM™ 400 materials for contamination or damage.

- Verify that materials meet the manufacturer’s specifications.

Mixing Process:

- Follow instructions for accurate mixing.

- Ensure a uniform and homogeneous mixture.

Application Techniques:

- Use recommended application methods.

- Ensure proper consolidation and uniform coverage.

Curing and Setting:

- Follow instructions for proper curing.

- Provide suitable conditions for setting and strength development.

Post-Application Inspection:

- Inspect the repaired area for defects or inadequate bonding.

- Address issues promptly and document corrective actions.

Documentation:

- Maintain comprehensive records of the quality control process.

- Document materials, ratios, techniques, curing conditions, and inspection findings.

By implementing these quality control measures, contractors can ensure the successful application of PRM™400 and achieve durable and reliable concrete repairs.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

Is polymer repair mortar used to repair concrete surfaces?

Polymer repair mortar is commonly used for a wide range of concrete repair applications including honeycomb, bolt holes, accidental damage, fractures and filling gaps and cavities.

Is polymer repair mortar suitable for repairing concrete coatings on rebars?

Yes, this type of mortar is a good option for coating on rebars.

Is polymer repair mortar used for vertical surfaces?

Yes, due to its instant setting, polymer repair mortar is a good choice for use on vertical surfaces.

How many components does polymer repair mortar have?

This polymer repair mortar is in two components: powder (25 kg) and polymer liquid (5 liters).

How to apply repair mortar in thicknesses less than 5 cm?

After preparing the concrete surface, the mortar is sprayed on the damaged concrete surface by spraying manually or by using a special spraying device (shotcrete). In the second method, the damaged area can be repaired using a spatula.

What measures should be taken to apply a mortar layer thickness of more than 5 cm?

After preparing the concrete surface to apply the repair mortar, formwork (molding) is performed and then the concrete surface repair mortar is applied.

Is Afzir Company Polymer Concrete Repair Mortar, used for chemical and corrosive environments?

In the chemical composition of polymer concrete repair mortar, strong compounds with anti-corrosion ability of concrete are used, which are suitable for working in chemical environments.

Does the polymer concrete repair mortar suffer from surface cracks after application?

This mortar is non-shrinking; therefore, it prevents the formation of surface cracks.

Why does not separation from the bed surface occur after working with polymer repair mortar?

Due to having a coefficient of thermal expansion close to concrete, it prevents the repair mortar from separating from the bed concrete because it suffers from expansion due to heat change.

Be the first to review “Polymer Modified Repair Mortar”