PRODUCT DESCRIPTION

Intumescent Based Fireproof Coating is a cutting-edge solution designed to protect steel structures from the devastating effects of fire. This advanced coating is specifically engineered to provide exceptional fire resistance, ensuring the safety and integrity of steel components in various applications.

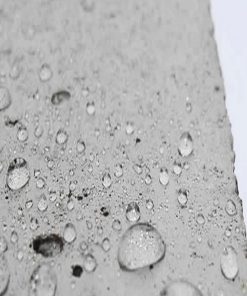

The coating’s unique formulation consists of paint-like materials that remain inert at lower temperatures, maintaining the structural integrity of the steel. However, when exposed to elevated temperatures typically ranging from 200-250°C, the coating undergoes a remarkable chemical reaction. This reaction triggers the intumescent properties of the coating, causing it to swell and form an expanded layer of low conductivity char.

The expanded char layer acts as an effective thermal barrier, significantly reducing heat transfer to the underlying steel structure. By forming this insulating layer, our Intumescent Based Fireproof Coating effectively delays the effects of fire, providing crucial time for evacuation and firefighting efforts.

In addition to its exceptional fire resistance, our coating offers several key advantages. Its lightweight nature minimizes any additional load on the structures, making it suitable for various applications, including high-rise steel structures. The coating also boasts an aesthetically pleasing finish, eliminating the need for additional surface coatings.

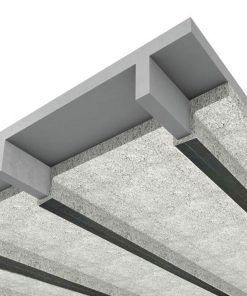

Application of the Intumescent Based Fireproof Coating is straightforward and can be applied to a variety of steel components, including beams, columns, pipes, and chimneys. With a maximum thickness of 6 mm, the coating creates a smooth surface that is resistant to abrasion and dust, ensuring long-lasting performance and ease of maintenance.

Our Intumescent Based Fireproof Coating is rigorously tested and certified to meet the highest industry standards for fire protection. It offers a significant level of fire resistance, with a proven capability to protect steel structures for up to 3 hours, providing valuable time for emergency response measures.

Choose our Intumescent Based Fireproof Coating to enhance the fire safety of your steel structures. With its innovative formulation, exceptional fire resistance, and ease of application, it is the ideal choice for ensuring the durability, safety, and peace of mind in various construction projects.

Key Features

- Smooth and durable surface against abrasion and dust

- Has a thin coating

- An affordable solution

- Easy repairs

- Compatible volatile organic compounds

- In accordance with modern world standards

- Ability to protect the structure against fire for up to 3 hours

Applications

- In general, intumescent paint can be used to reinforce structures that are relatively large, such as shopping malls and airports.

- Suitable for beams, columns and interior spaces

- Suitable for pipes, gutters and chimneys

- Suitable for large structures such as industrial plants, production units, parking of commercial complexes

- Can be used in public spaces for families, railways and car terminals

- Can be used in ports and high environments

Packaging

- –

Colour

- light pink

technical specifications

| Color |

Light pink |

| Wet film thickness |

1.14 mm for each layer |

| Dry film thickness |

0.8 mm for each layer |

|

Percent solids |

67% |

| Solvent |

Yes |

|

Shelf time |

18 months |

| Flammability |

At 30 ℃ |

|

Compressive strength |

7.9 MPa |

- Familiarize Yourself with the Coating: Understand the properties and application techniques of the Intumescent Based Fireproof Coating.

- Conduct Structural Analysis: Evaluate fire protection requirements for steel components through a comprehensive structural analysis.

- Collaborate with Fire Protection Experts: Seek guidance from specialists to optimize coating application and ensure compliance.

- Consider Coating Thickness: Incorporate the specified maximum thickness into structural calculations and design considerations.

- Integrate Coating Application into Construction Timeline: Plan and coordinate coating application to avoid delays and interference.

- Follow Application Guidelines: Adhere strictly to manufacturer’s guidelines for surface preparation, application techniques, and environmental conditions.

- Quality Control and Testing: Implement thorough quality control processes and regular testing of the applied coating.

- Documentation and Record-Keeping: Maintain detailed records of the application process for future reference.

- Coordinate with Other Trades: Collaborate with relevant parties to address potential conflicts and challenges.

- Continuous Education and Stay Updated: Stay informed about advancements, regulations, and best practices in fireproof coatings.

- Familiarize Yourself with the Coating: Understand the properties and limitations of the Intumescent Based Fireproof Coating.

- Train Your Workforce: Provide proper training on application techniques and safety protocols.

- Coordinate with Engineers and Designers: Collaborate closely to integrate the coating into the construction process.

- Plan for Surface Preparation: Develop a thorough plan for cleaning and preparing surfaces for coating application.

- Create a Controlled Application Environment: Maintain ideal conditions for temperature, humidity, and ventilation.

- Follow Manufacturer Guidelines: Adhere to recommended mixing ratios, thicknesses, and curing times.

- Implement Quality Control Measures: Conduct regular inspections and tests to ensure compliance and performance.

- Monitor Weather Conditions: Avoid adverse weather during coating application.

- Document Application Details: Keep records of dates, procedures, thicknesses, and challenges.

- Coordinate with Other Trades: Communicate effectively with other trades involved in the project.

Surface temperature for processing should be maintained at 25 degrees Celsius. The intumescent paint has a final setting time of 24 hours, after which the final coating can be applied to the surface.

How to use:

Interior Application:

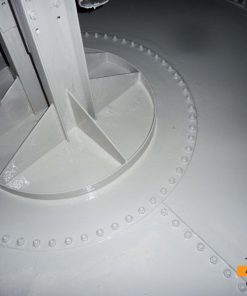

- Apply a compatible steel primer to the steel substrate as the first step of the intumescent system.

- Next, apply the intumescent base coat to the primed steel substrate, ensuring the required thickness for effective fire protection of the structural member.

- Finally, apply a decorative and protective top coat over the intumescent coating. This finish coat can be of any color and gloss level, and it should be a material capable of safeguarding the intumescent coating from high humidity and other potentially harsh interior environmental conditions. Additionally, it should provide a smooth and visually appealing architectural finish.

Exterior Application:

- Begin by applying a compatible steel primer to the steel substrate as the first step of the intumescent system.

- Apply the intumescent base coat to the primed steel substrate, ensuring the required thickness for effective fire protection.

- Apply two coats of Afzir’s Spray Film Top seal over the intumescent paint.

- Finally, apply a decorative and protective top coat approved by Afzir Company over the installed Top seal. This exterior finish coat can be of any color and gloss level, and it must meet Afzir’s specific approval criteria. The finish coat will protect the Afzir intumescent paint system while providing a smooth and visually appealing architectural finish.

- Establish QC Procedures: Develop a comprehensive plan for quality control specific to the application of Intumescent Based Fireproof Coating.

- Training and Qualifications: Ensure QC personnel are properly trained and qualified for their roles.

- Surface Preparation Inspection: Inspect surfaces to verify cleanliness, dryness, and smoothness before coating application.

- Adhesion Testing: Perform tests to assess the bonding strength between the coating and substrate.

- Thickness Measurement: Regularly measure coating thickness using non-destructive testing methods.

- Visual Inspection: Conduct visual inspections for uniformity, coverage, and defects throughout the application process.

- Cure and Dry Time Verification: Monitor and confirm the coating has achieved the specified cure and dry time.

- Fire Resistance Testing: Collaborate with accredited laboratories to test coated samples for fire resistance.

- Documentation and Record-Keeping: Maintain detailed records of QC activities, including reports and test results.

- Continuous Improvement: Evaluate and improve QC procedures based on feedback and implement corrective actions when necessary.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

What is intumescent paint?

intumescent paints or coatings help to increase the building's fire resistance. These coatings expand when exposed to extreme temperatures. Coatings lose their density as they shrink. As a result, they act as an insulator.

What is the advantage of intumescent fire retardant paints?

The significant advantage of this type of coating over other coatings, such as mineral coatings, is their beauty and lightness. Because this product itself can be used as a final surface coating.

What is the maximum thickness of intumescent paints on surfaces?

intumescent paints are applied with a maximum thickness of 6 mm and finally create a smooth surface and resistant to abrasion and dust.

On what surfaces are intumescent fire retardant paints most commonly used?

intumescent fire-retardant paints are used on steel structures, and in general, intumescent paints can be used to reinforce large-scale structures, such as shopping malls and airports, against fire.

What is the durability of intumescent paints against fire?

These paints give more resilience to steel surfaces for up to 3 hours.

In what colors are intumescent fire retardant paints produced?

Expandable fire retardant paints are light pink.

How long does it take for the intumescent paint to reach its final setting?

The final setting time of the intumescent paint is 24 hours. After this time, the final coating can be applied on the surface.

Be the first to review “Intumescent Based Fire proof Coating”