PRODUCT DESCRIPTION

Features

- Special epoxy base glue for steel jacket reinforcement

- Very high initial and final adhesion strength

- in two types of high viscosity (gel) and low viscosity (liquid)

- It is easy to mix and use

- Very good resistance under permanent loads

- Adheres well to all types of concrete surfaces.

- hardening without shrinkage (cracking)

- Resistant to impact and temperature changes

- Excellent chemical stability

Applications

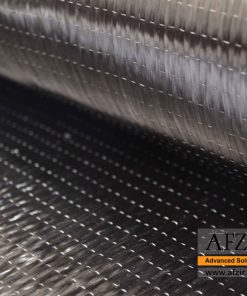

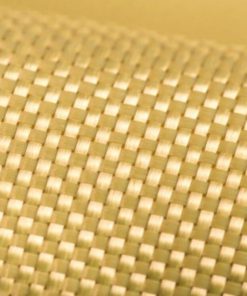

- The steel jacket epoxy glue, which has very high adhesive properties, is used to stick steel sheets to various types of concrete surfaces, in the steel jacket strengthening system.

Packaging

- Buckets A=20 kg and B=10 kg

Colour

- Gray

technical specifications

| Base material |

Resin epoxy |

|

density |

1.65Kg/L |

| compressive strength |

90MPa |

| Tensile strength |

30MPa |

| Rupture strain |

4% |

| Operating temperature |

-40 to 65 ℃ |

Here is a summarized list of recommendations for engineers working with The Steel Jacketing Adhesive:

- Follow manufacturer guidelines for proper usage.

- Prepare concrete surfaces thoroughly before applying the adhesive.

- Adhere to safety protocols and wear appropriate PPE.

- Test adhesive compatibility before large-scale application.

- Consider temperature and environmental conditions during application and curing.

- Monitor and allow sufficient curing time as recommended.

- Conduct regular inspections to ensure adhesive performance.

- Consult with structural engineering professionals for project-specific guidance.

Here is a summarized list of recommendations for contractors working with The Steel Jacketing Adhesive:

- Familiarize yourself with the product and manufacturer’s instructions.

- Properly prepare concrete surfaces before application.

- Follow recommended mixing ratios and application techniques.

- Ensure proper adhesive coverage on steel plates and concrete surfaces.

- Allow sufficient curing time and adhere to recommended conditions.

- Conduct regular inspections and quality control checks.

- Maintain safety precautions and use appropriate PPE.

- Collaborate with engineers for guidance and project-specific input.

Application Instructions for The Steel Jacketing Adhesive:

- Surface Preparation: a. Ensure the concrete surfaces are clean, dry, and free from loose particles or contaminants. b. If necessary, roughen the concrete surface using suitable methods such as sandblasting or mechanical abrasion to improve adhesion.

- Mixing: a. Follow the manufacturer’s instructions regarding the mixing ratios and proportions of epoxy resin and hardener. b. Use clean, dry mixing tools and containers to prevent contamination.

- Application: a. Apply a thin, even layer of The Steel Jacketing Adhesive onto the prepared concrete surface using a suitable application tool such as a brush or roller. b. Ensure that the adhesive is spread uniformly to achieve full coverage.

- Steel Plate Placement: a. Carefully position the steel plates onto the adhesive-coated concrete surface. b. Apply sufficient pressure to ensure good contact between the steel plates and the adhesive.

- Additional Adhesive Application: a. Apply an additional adhesive layer over the steel plates, covering the entire surface for enhanced bonding. b. Use a suitable tool to ensure an even and uniform application.

- Curing: a. Allow the adhesive to cure per the manufacturer’s recommended curing time and conditions. b. Avoid subjecting the bonded area to excessive loads or stresses during curing.

- Quality Control: a. Regularly inspect the bonded area for any signs of failure or defects. b. Conduct necessary quality control tests to ensure the adhesive’s effectiveness and adherence to project requirements.

- Safety Precautions: a. Adhere to safety guidelines and use appropriate personal protective equipment (PPE) during application. b. Provide adequate ventilation in enclosed areas to minimize exposure to fumes.

Here is a summarized guide to quality control of The Steel Jacketing Adhesive:

- Visual Inspection: Ensure uniform adhesive coverage for visible defects.

- Adhesion Testing: To assess bond strength between steel plates and concrete surfaces, perform tests.

- Durability Testing: Evaluate resistance to moisture, temperature, chemicals, and aging.

- Load Testing: Apply controlled loads to evaluate resistance to mechanical forces.

- Non-Destructive Testing (NDT): Use techniques to assess bond integrity without damaging the assembly.

- Record Keeping: Maintain detailed records of tests, parameters, and curing conditions.

- Compliance with Standards: Ensure procedures align with industry standards and project requirements.

- Regular Monitoring: Monitor performance and durability over time, and conduct periodic inspections.

Note: Refer to manufacturer recommendations, project requirements, and industry standards for detailed guidance on quality control procedures.

technical documents

Photo Gallery

Technical documentation request

Be the first to review “Steel Jacketing Adhesive”