PRODUCT DESCRIPTION

Epoxy grout is a specialized grouting material formulated with a three-component system. When mixed with water, this grout does not shrink or experience volume reduction, making it suitable for various applications such as flooring, rebar planting, and filling cavities beneath base plates. It can also be used to level the surface of base plates. Specifically, ERG™300 is a highly volatile, three-part epoxy grout designed for thicknesses ranging from 1″ (25.4mm) to 8″ (203.2mm).

Formulated using special epoxy resins and well-graded materials, epoxy grout offers easy grouting in spaces with a 20 to 100 mm width. The following sections will discuss the differences between three-component epoxy grout and cement grout, application methods, properties, features, specifications, and pricing.

WHEN TO USE THREE-COMPONENT EPOXY GROUT

Selecting the appropriate type of epoxy grout depends on the specific requirements of the project at hand. Factors such as environmental conditions, on-site applicability, stability, and durability should be taken into consideration. For instance, gravity grouting is recommended for small base plates, while larger areas and volumes necessitate high flowability and efficiency grouts.

Consider the following points when choosing and applying grout:

- Grouting can be done by gravity or by a pump. Pump grouting ensures a constant and uniform pressure, eliminating air entrapment in the grout.

- Pump grouting allows for achieving maximum resistance with minimal grout thickness. In contrast, gravity grouting requires observing restrictions related to the minimum thickness of the grout, depending on its plastic, liquid, or fluid states.

- Expanding grouts are more suitable in weather conditions where moisture loss is likely.

- Three-component epoxy grout is ideal for high-pressure applications such as wind turbines, gas transmission and crane rail installations, offshore structures, and machine base plate installations exposed to dynamic loading and continuous vibrations from heavy industrial equipment.

- It can be used when installing new equipment, base plates, anchoring, and when the grout is subject to chemical attacks and severe vibration. Its excellent resistance to impact and vibration loading ensures no damage, even under extreme dynamic loads.

THREE-COMPONENT EPOXY GROUT PACKAGING

ERG™300 three-component epoxy grout is available in standard units:

- Part A (resin): 20 kgs and 10 kgs buckets.

- Part B (hardener): 10 kgs and 5 kgs buckets.

- Part A and Part B are supplied in plastic buckets,

while Part C is available in 30 kg and 15 kg bags.

THREE-COMPONENT EPOXY GROUT PRICING

The price of epoxy grout varies per square meter. Factors such as the type of grout execution, materials used, and project size impact the cost. To estimate the total cost, calculate the required amount of grout by measuring the dimensions of the area to be grouted (length, width, and height). Once the volume is determined, the cost per square meter can be calculated based on the chosen grout type.

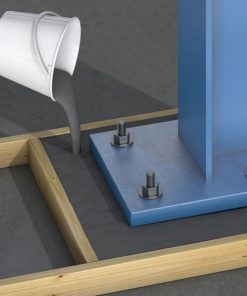

BENEFITS OF USING THREE-COMPONENT EPOXY GROUT UNDER BASE PLATES

Due to its high efficiency, fluidity, and ability to fill corners and pores, epoxy grout is highly suitable for filling the base of columns. It offers a strong connection and adhesion between the foundation concrete and the column plate or plates. Its rapid setting speed further enhances its effectiveness.

DIFFERENCES BETWEEN EPOXY GROUT AND ORDINARY GROUT

Compared to cement grout, which consists of cement powder, three-component epoxy grout stands out with its unique characteristics. Here are some notable differences between epoxy grout and ordinary grout:

Tensile and Flexural Strength:

Three-component epoxy grout exhibits higher tensile and flexural strength than cement grout. This enhanced strength provides superior resistance to cracking, making it suitable for demanding applications.

Load Tolerance:

Epoxy-based grout demonstrates superior resistance to both dynamic and static loads compared to cement-based grout. This makes it a preferred choice for installations subjected to heavy loads and continuous vibrations.

Connection and Adhesion:

Epoxy grout creates a stronger connection and adhesion between the foundation concrete and the column plate or plates. This ensures enhanced structural stability and durability.

Resistance:

Epoxy grouts are known for their exceptional resistance properties. They offer increased resistance to chemicals, stains, moisture, and abrasion, making them ideal for use in environments where durability is crucial.

Compressive Strength:

Three-component epoxy grout provides optimal compressive strength within a relatively short time frame. It reaches its maximum strength between 24 to 48 hours after grouting, allowing for faster project completion.

Application Time:

Epoxy-based grouting has a faster application time compared to regular grouting. Its quick-setting properties enable efficient installation and minimize project timelines.

Price:

It’s important to note that the cost of three-component epoxy grout can be higher than that of ordinary grout. The increased durability, strength, and specialized properties of epoxy grout contribute to its higher price point.

Considering these differences, three-component epoxy grout is often favored for projects that require enhanced performance, durability, and resistance to various factors such as heavy loads, chemical exposure, and moisture.

In summary, three-component epoxy grout offers superior strength, load tolerance, adhesion, and resistance compared to ordinary grout. Its unique properties make it an excellent choice for demanding applications where durability and performance are paramount.

Features

- Excellent adhesion of three-component epoxy grout to concrete, steel and most building materials

- Obtaining excellent initial and final mechanical resistances

- Excellent chemical stability

- Excellent stability against static and moving loads of structures

- Easy mixing and application of three-component epoxy grout

- Insignificant smell and safe for users

- Very good flow even in limited spaces and thin layers

- Non-shrinkage of three-component epoxy grout during curing

- Prevent corrosion of reinforcements

- No need for primer

Applications

- Using three-component epoxy grout as a repair grout to fill holes and cracks in concrete.

- Grouting in limited spaces under the columns, under the baseplates, equipment and industrial machines that have fixed and moving loads.

- Installation of transmission cables and heavy factory machinery baseplates.

- Installing screws, planting rebar and planting bolts in concrete.

Packaging

- Three-components buckets

Colour

- gray slurry (after mixing)

technical specifications

| Physical characteristics |

dark gray paste (after mixing) Component A: white paste Component B: Gray paste Component C: Powder |

|

Mixing ratio |

A : B : C : = 2 : 1 : 2 |

| Pot life |

20min |

|

Finial setting time |

14 days |

| application temperature |

-35 to 65℃ |

|

density |

1.2Kg/L |

| compressive strength (14 days) |

88MPa |

|

adhesive strength (14 days) |

5.2MPa |

|

tensile strength (14 days) |

15MPa |

| flexural strength 14 days) |

25MPa |

- Surface Preparation: Ensure surfaces are clean and free from debris.

- Follow Manufacturer’s Guidelines: Adhere to mixing ratios, application, and curing instructions.

- Compatibility Testing: Test compatibility with substrates before full-scale application.

- Adequate Mixing: Thoroughly mix components according to recommended ratios.

- Proper Application: Apply grout evenly, filling voids and gaps completely.

- Consider Environmental Conditions: Account for temperature and humidity during application and curing.

- Safety Measures: Use appropriate safety precautions and equipment.

- Regular Quality Control: Monitor and inspect grout for defects or inconsistencies.

- Document and Communicate: Maintain detailed records and share information with stakeholders.

- Seek Expert Advice: Consult experts or manufacturers for technical support when needed.

- Minimum Execution Thickness: Maintain a minimum thickness of 20 mm during grout application.

- Maximum Execution Thickness: Avoid exceeding a maximum thickness of 100 mm for optimal results.

- Gravity Grouting Method: Increase thickness by approximately 13 mm for every additional 300 mm of run length, up to a maximum of 100 mm.

- Temperature Considerations: Avoid grouting below 5°C to ensure proper performance.

- Avoid Diluting Solution: Do not use a diluting solution or solvent as it may impact grout properties.

- Use Fully Cured Concrete: Apply the grout to 21 to 28 days old and fully cured concrete.

- High-Temperature Exposure: Consider the impact of high temperatures on the grout’s properties and follow ACI 351.1R-99 recommendations.

Substrate Preparation:

- Clean the concrete surface from dust and oil, and remove any damaged parts.

- Chemical cleaners can be used for effective cleaning of the substrate.

Mixing the Three-Component Epoxy Grout:

- Open the buckets of resin (part A) and hardener (part B).

- Pour the hardener into the resin bucket and stir the mixture with a spatula or hand mixer until it achieves a uniform color.

- Mixing can also be done using low-speed and high-speed mixers, ensuring that air bubbles are not introduced. Avoid over-mixing, as it can impact grout quality.

Grouting Process:

- Start pouring the mixed grout from one side in a continuous manner to eliminate air entrapment.

- Maintain a continuous flow of grouting throughout the application.

- Ensure sufficient grout is available before starting the grouting process.

- Pay attention to the pot life of the product, which indicates the maximum time available for workability.

Processing of Epoxy Grout:

- To retain moisture and promote proper curing, the epoxy grout should be cured using special curing agents or by covering it with a wet sack.

- Depending on weather conditions, the curing process may continue for up to three days.

- After the curing period, it is recommended to apply compressive strength gradually by subjecting the grouted area to loading.

Following these application instructions, you can ensure the proper preparation, mixing, and grouting of ERG™300 Three-Component Epoxy Grout for effective results.

Safety Precautions for ERG™300 Three-Component Epoxy Grout:

- Avoid inhaling epoxy grout fumes.

- When the concentration of grout vapor is high, use local ventilation devices and wear masks to minimize inhalation of harmful gases.

- Keep epoxy grout away from fire, as burning epoxy materials release dangerous fumes.

- Prevent skin or eye contact with epoxy grout. If contact occurs, wash the affected skin with soap and water. In case of eye contact, rinse thoroughly with water for 15 minutes.

- Before using epoxy grout, carefully read and follow all precautions, specifications, and properties listed on the product.

By following these safety guidelines, you can ensure the safe handling and use of ERG™300 Three-Component Epoxy Grout.

technical documents

Photo Gallery

Technical documentation request

Be the first to review “Three Component Epoxy Grout”