PRODUCT DESCRIPTION

Epoxy putty is a versatile adhesive that hardens at room temperature, making it ideal for various applications. It consists of two components with a clay-like consistency combined prior to use. When these components are kneaded together, they undergo an exothermic chemical reaction that activates the putty by catalyzing an epoxide polymerization process. Unlike many other glues, epoxy adhesive can effectively fill gaps and even be molded into structural parts.

Some manufacturers advertise that their cured product can be drilled and tapped and that it achieves a hardness comparable to steel (measured by Shore rating). However, it is important to note that their tensile strength and shear strength are considerably lower than steel’s.

Epoxy putty is a reliable and versatile adhesive that offers various applications in various industries and DIY projects. Its unique formulation combines convenience, durability, and excellent bonding capabilities, making it a go-to choice for professionals and hobbyists.

One of the critical advantages of epoxy putty is its room-temperature-hardening feature. This means that it cures and hardens without the need for additional heat or special curing equipment. Once the two components of the putty are thoroughly mixed together, a chemical reaction is triggered, initiating the hardening process. This allows for easy and hassle-free application, saving both time and effort.

The versatility of epoxy putty is a notable attribute. Its ability to fill gaps, cracks, and voids makes it an exceptional space-filling adhesive. Whether you need to repair damaged surfaces, join different materials, or create custom-shaped parts, epoxy putty provides a reliable and durable bond. It can even be molded into various forms, allowing for design and structural reinforcement flexibility.

Another noteworthy characteristic of epoxy putty is its adhesion properties. It exhibits excellent bonding strength not only to common materials like wood, metal, and plastic but also to challenging surfaces such as concrete and ceramics. This makes it a valuable tool for repairing and reinforcing a wide range of objects and structures.

While some manufacturers claim that their epoxy putty products can be drilled and tapped after curing, it is important to note that their strength may not match that of steel. However, when applied correctly and used within their intended purpose, these cured products offer sufficient stability and resilience for many applications.

In summary, epoxy putty is a versatile, easy-to-use adhesive with reliable bonding, gap-filling, and molding capabilities. Its room-temperature-hardening feature and excellent adhesion properties make it a valuable asset in repair, construction, crafting, and various other projects. Choose epoxy putty for its convenience, durability, and ability to bring your ideas to life.

Key Features

- Excellent chemical resistance

- Very high coating resistance and excellent impact resistance

- Applicable on thin sections

- More physical strength than conventional cement systems

- Economically viable

- Easy to transport and run

- Easy combination

- High chemical resistance and corrosion and solvents

- No flow or seal

- No shrinkage during drying

- Suitable for application on horizontal and vertical surfaces

Applications

- Can be used in indoor and outdoor applications

- Applicable on sharp edges

- Connecting new concrete to old concrete

- Concrete crack repair

- Leveling and fixing of the decks of bridges and as metal anti shock, Leveling and setting of different levels for the installation of FRP and FRP laminates in retrofitting projects

- Repairing of damaged concrete surfaces and surface cavities in different horizontal, vertical or overhead modes

- Filling the screws and holes

- Leveling the underlying ceilings and beams

Packaging

- Two components buckets

Colour

- Grey paste

technical specifications

| Chemical base |

Resin epoxy |

| color |

Gray paste |

| Shelf time |

24 months |

| Layer thickness |

10 mm |

|

subgrade temperature |

5℃ – 35℃ |

| Curing time |

12 hours and the final one in 7 days |

| Minimum compressive strength |

10 MPa |

| Minimum tensile strength |

0.8 MPa |

| Chemical resistance |

Resistant to dilute acid and alkali |

Summary of recommendations for engineers working with two-component epoxy mortar:

Familiarize yourself with the product:

- Understand the characteristics and properties of the specific epoxy mortar.

- Read the manufacturer’s instructions and safety guidelines.

Ensure proper surface preparation:

- Thoroughly clean the concrete bed to remove contaminants.

- Use recommended methods such as mechanical tools or sandblasting.

Adhere to mixing instructions:

- Follow the manufacturer’s guidelines for accurate measurement and thorough blending.

Use appropriate application techniques:

- Apply the epoxy mortar directly using suitable tools like trowels.

- Achieve recommended thickness and ensure even coverage.

- Utilize a wet trowel for smoother surfaces if needed.

Consider environmental conditions:

- Take into account temperature, humidity, and curing time recommendations.

- Maintain suitable conditions during the application and curing stages.

Monitor safety precautions:

- Follow safety protocols and wear proper PPE.

- Ensure adequate ventilation in enclosed areas.

Follow maintenance and storage guidelines:

- Store the epoxy mortar in unopened packaging within recommended temperature range and away from direct light.

Seek professional advice when needed:

- Consult technical experts or the manufacturer’s support team for guidance and troubleshooting.

By following these recommendations, engineers can ensure the successful application and performance of two-component epoxy mortar in their projects.

- Understand the project requirements.

- Select the appropriate epoxy mortar product for the project.

- Ensure proper substrate preparation, including thorough cleaning and surface profiling.

- Adhere to accurate mixing ratios and instructions provided by the manufacturer.

- Plan for efficient application, considering factors such as ambient temperature and working time.

- Follow proper application techniques, applying the epoxy mortar evenly and at the recommended thickness.

- Monitor curing and drying times for appropriate subsequent work or layer scheduling.

- Provide proper ventilation and adhere to safety measures, wearing appropriate PPE.

- Maintain proper storage and disposal practices for unused epoxy mortar components.

- Seek professional assistance or guidance from technical experts if needed.

To ensure successful application and maintenance of Afzir’s two-component epoxy mortar, the following points should be considered:

Bed preparation:

The concrete bed should be strong, free from contaminants, and cleaned thoroughly using mechanical tools or sandblasting. Newly poured concrete should be allowed to cure for at least 28 days.

Mixing:

Each pack contains the necessary amounts of resin and hardener, which should be mixed separately before combining them into a homogeneous mixture. Mixing at room temperature is recommended.

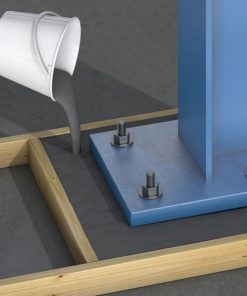

Application:

The epoxy mortar can be applied directly to the desired surfaces without the need for special tools or primers. It can be poured onto the surface and spread evenly using a trowel. For a surface area of 0.75 square meters and a thickness of 2 mm, 2 kg of the mortar is sufficient.

Maintenance:

Store the unopened packages of Afzir’s two-component epoxy mortar in a temperature range of 5 to 35 °C, away from direct light.

technical documents

Photo Gallery

Technical documentation request

Frequently Asked Questions

What does two-component epoxy mean?

Epoxy is a two-component adhesive consisting of a mixture of epoxy resin and hardener. The two ingredients are combined in the desired containers and are mixed only when you are ready to paste.

What is the unique feature of two-component epoxy mortar?

This gray concrete restorative mortar does not require a primer and creates a uniform surface.

What is epoxy mortar?

Epoxy mortar is a unique and popular grout that does not use Portland cement or water in the mixing process. Contains hardener, pigment, epoxy resin and silica fillers. Epoxy mortar has less porosity than cement grout.

Where is two-component epoxy mortar most used?

This product with excellent adhesion to concrete, building materials and steels is ideal for permanent repair of damaged concrete on horizontal and vertical surfaces, broken stairs.

What is the chemical resistance of epoxy mortar?

Two-component epoxy mortar is resistant to dilute and alkaline acids.

What is the product color of two-component epoxy mortar?

The color of the product is a two-component epoxy mortar with a gray color (after mixing).

What tool is used to apply two-component epoxy mortar on surfaces?

A variety of steel trowels are used to polish surfaces.

What is the strength of two-component epoxy mortar?

Depending on the temperature of the curing medium, two-component epoxy mortar can achieve 28-day strength of concrete in 24 hours.

Be the first to review “Two Component Epoxy Repair Mortar”