PRODUCT DESCRIPTION

Vinyl Ester Resin Mortar is an advanced construction material designed to provide exceptional resistance in aggressive chemical environments, establishing itself as one of the market’s leading corrosion-resistant solutions. Engineered with meticulous precision, this mortar exhibits outstanding durability, making it the ideal choice for applications that demand superior protection against harsh substances.

This mortar is formulated with advanced vinyl ester resin and delivers unparalleled resistance to various chemicals. It effectively withstands concentrated oxidizing acids, such as nitric acid (up to 50% concentration), sulfuric acid (up to 75% concentration), hydrochloric acid (up to 36% concentration), phosphoric acid (up to 85% concentration), sodium hydroxide (up to 50% concentration), and sodium hypochlorite. Furthermore, it offers formidable resistance to hydrofluoric acid (combined with a carbon-based filler) and numerous concentrated alkalis and salts.

Beyond its exceptional chemical resistance, Vinyl Ester Resin Mortar excels in thermal stability, ensuring optimal performance even in extreme temperature conditions. This characteristic renders it suitable for deployments in environments where both chemical aggression and elevated temperatures pose challenges.

For ease of use, the mortar is provided in two parts: powder and liquid components. These components contain a precise blend of vinyl ester resin, accelerator, catalyst, and filler. Before application, achieving accurate and proportionate mixing of these components is crucial. Once mixed, the mortar can be effortlessly applied to diverse surfaces, including concrete and steel, forming a robust protective coating.

Vinyl Ester Resin Mortar finds wide-ranging applications across industries such as chemical processing, wastewater treatment, power generation, and petrochemical plants. It is commonly employed for lining and safeguarding tanks, pipes, containment structures, floors, and other critical infrastructure exposed to corrosive substances.

Rely on Vinyl Ester Resin Mortar for unparalleled corrosion resistance, granting you peace of mind in challenging chemical conditions. To obtain further information or inquire about purchasing this exceptional product (ARVMTM code) based on vinyl ester resin, do not hesitate to contact our knowledgeable experts for comprehensive assistance.

Features

- Resistant to strong oxidizing agents, acids, alkalis and bleaches and solvents.

- High thermal resistance

- No wear and tear

- High adhesion, tensile and compressive strength.

- Improving physical properties

Applications

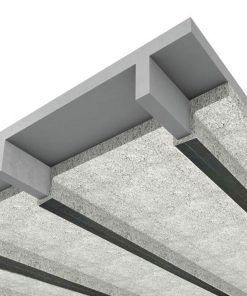

- build floors, tiling, etc.

- Protective coating of surfaces that are in the vicinity of destructive chemicals.

- Protective covering of wells, reservoirs, trenches and towers

- Protective coating of food factories

- Protective cover for laboratories, textile, steel

- Protective cover of pulp and paper factories

- Protective cover of chemical and detergent factories

- Protective cover of chemical fertilizer factories

- Protective covering of sulfuric acid and sulfur production plants and their storage tanks

Packaging

- In 50Kg pockets

Colour

- white

technical specifications

|

Gel time |

20-30 min |

|

density |

1.7-1.75 gr per cc |

| water adsorption |

0.30% |

|

Bond strength |

10 kg/CM2 |

|

Compressive strength |

500 kg/CM2 |

| Flexural strength |

300 kg/CM2 |

- Surface Preparation: Ensure that the surfaces to be coated with the mortar are clean, dry, and free from contaminants to ensure optimal adhesion.

- Accurate Mixing: Carefully measure and mix the mortar components in the correct proportions to achieve the desired performance and chemical resistance properties.

- Application Techniques: Use appropriate application techniques, such as troweling or spraying, to achieve even coverage and the proper thickness of the mortar for adequate protection.

- Curing and Drying: Allow sufficient time for the mortar to cure and dry according to the manufacturer’s recommendations, considering factors like temperature and humidity.

- Quality Control: Regularly inspect and test the coated surfaces to ensure compliance with project requirements, including checks for adhesion, thickness, and chemical resistance.

- Safety Precautions: Prioritize safety by wearing the necessary personal protective equipment (PPE), following proper ventilation procedures, and disposing of waste materials correctly.

- Ongoing Maintenance: Conduct regular inspections and maintenance of the coated surfaces to promptly address any damage or wear, ensuring long-term performance.

- Consult Experts: Seek advice and consultation from experts or manufacturers’ technical support teams for specific project requirements, troubleshooting, or any concerns related to the mortar.

- Familiarize with Specifications: Review project requirements and scope of work.

- Procure High-Quality Materials: Source mortar from reputable suppliers meeting standards.

- Train Personnel: Provide training on handling and application techniques.

- Surface Preparation: Clean and prepare surfaces according to guidelines.

- Mixing and Application: Follow instructions for accurate mixing and apply evenly.

- Quality Control: Conduct inspections to ensure adherence to specifications.

- Curing and Protection: Allow sufficient curing time and protect from weather.

- Safety Measures: Ensure proper PPE and handle waste safely.

- Documentation and Reporting: Maintain records and report deviations.

- Collaboration with Manufacturers: Seek technical support for troubleshooting and challenges.

Surface preparation:

- Ensure surfaces are clean, dry, and contaminant-free.

Performance:

- Thoroughly stir resin before use.

- Mix liquid, accelerator, catalyst, promoter, and powder according to the specified plan until a uniform mixture is achieved.

- Use all mortar from the mixing bowl before preparing another batch.

- Avoid direct contact between the catalyst and accelerator to prevent explosions.

Setting and curing:

Vinyl ester self-hardens when all components are mixed. The initial setting occurs in 2 hours at 30°C. The final setting occurs in 24-36 hours at 30°C. Curing time is 7 days at 30°C.

- Establish a Quality Control Plan: Develop a comprehensive plan outlining procedures and inspection points.

- Inspection of Incoming Materials: Thoroughly inspect materials for compliance and defects.

- Batch Testing: Conduct tests to verify mortar properties and performance.

- Surface Preparation Verification: Verify surfaces are properly prepared before application.

- Adhesion Testing: Assess bond strength between mortar and substrate.

- Thickness Measurement: Regularly measure mortar thickness to meet specifications.

- Chemical Resistance Testing: Evaluate mortar performance against corrosive substances.

- Visual Inspection: Identify visible defects or irregularities in the applied mortar.

- Documentation and Record Keeping: Maintain detailed records of quality control activities.

- Continuous Monitoring: Monitor long-term performance and address maintenance needs.

It is important to follow these safety guidelines to ensure personal well-being and mitigate potential risks associated with the product.

- Personal Safety: When handling the product, prioritize personal safety by wearing appropriate protective equipment (PPE) such as gloves, goggles, and work clothes.

- Skin Protection: Take necessary precautions to avoid skin contact with the product. If contact occurs, immediately wash the affected area with plenty of warm water and seek medical attention.

- Eye Protection: Protect eyes from potential exposure to the product. In case of contact with the eyes, rinse thoroughly with water and seek immediate medical assistance.

- Mucous Membrane Protection: Avoid contact with mucous membranes. If contact occurs, rinse the affected area with water and seek medical advice.

technical documents

Photo Gallery

Technical documentation request

Be the first to review “Acid Resistant Vinyl Ester Resin Mortar”