PRODUCT DESCRIPTION

The Three-component Epoxy Repair Mortar, known as ERM™ code 300, is a high-performance construction material designed to provide rapid strength development, superior mechanical properties, and exceptional chemical stability during the early curing stages. Its versatile nature enables its application for a wide range of purposes. This specialized epoxy mortar offers many capabilities, making it a widely favored choice for various construction and repair projects.

Its advanced formulation ensures that the Three-component Epoxy Repair Mortar achieves fast setting and curing times, allowing for efficient and timely repairs. With excellent bonding properties, this mortar effectively adheres to various substrates, including concrete, masonry, and metal surfaces, ensuring a long-lasting and reliable repair solution.

The Three-component Epoxy Repair Mortar, ERM™ code 300, exhibits exceptional mechanical strength, providing structural integrity and durability to repaired surfaces. Its high compressive and flexural strength make it suitable for repairing and strengthening concrete structures, such as columns, beams, and slabs. Additionally, its resistance to chemical substances, corrosives, and acids ensures its longevity in harsh environments.

This epoxy mortar is easy to apply, allowing for seamless installation on horizontal, vertical, and even overhead surfaces. Its non-flowing consistency ensures that the material stays in place during application, eliminating the need for additional support or formwork. This feature makes it ideal for repairing damaged areas at various heights and angles.

Whether used for repairing cracks, filling voids, or restoring damaged concrete surfaces, the Three-component Epoxy Repair Mortar, ERM™ code 300, offers a reliable and efficient solution. It is commonly employed in renovating, retrofitting, and maintaining buildings, bridges, parking structures, industrial facilities, and other infrastructure projects.

With its outstanding performance characteristics and wide-ranging applications, the Three-component Epoxy Repair Mortar, ERM™ code 300, stands as a trusted choice for contractors, engineers, and construction professionals seeking a dependable and high-quality repair mortar.

Features

- Excellent adhesion to concrete, steel and most building materials

- Superior initial and final mechanical resistances

- Excellent chemical stability

- Excellent stability against static and moving loads of structures.

- Easy to mix and application

- Insignificant smell and safe for users

- Very good flow even in limited spaces and thin layers

- Non-shrinkage when hardening

- No corrosion of reinforcements

- No need for primer

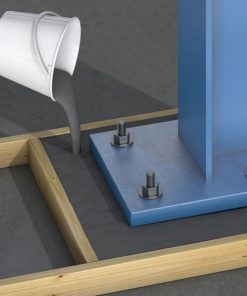

Applications

- Structural filling of cavities and concrete holes

- Repair of concrete surfaces

- Correction and repair of damaged edges of concrete seams

- Improvement and leveling of surfaces that need external reinforcement.

- As a bonding layer on concrete, steel, stone, wood, etc.

- As a coating resistant to wear and impact

- Considering that the base of this product is epoxy, it can also be used as a waterproofing material in some cases.

Packaging

- 25 and 50 kg packaging (total components)

Colour

- Gray paste (after mixing)

technical specifications

|

Appearance of the product |

Gray paste (after mixing) Component A: White Part B: grey Component C: Pale gray powder |

|

Mixing ratio |

A : B : C : = 2 : 1 : 2 |

| final setting time |

7 days |

| density |

1.45Kg/L |

|

Pot life |

60min |

| Operating temperature |

-35 to 65 ℃ |

| compressive strength |

35MPa |

| Adhesion stability |

2.5MPa |

Recommendations for Engineers Working with ERM™ Code 300:

Surface Preparation:

Thoroughly clean and prepare the repair area for optimal adhesion.

Follow Mixing Instructions:

Follow recommended ratios and procedures for proper mortar consistency.

Apply within Pot Life:

Work within the specified time frame to maintain desired properties.

Use Appropriate Tools:

Select suitable tools for application, ensuring they are clean and in good condition.

Consider Temperature and Humidity:

Account for ambient conditions during application and curing.

Proper Curing:

Follow recommended methods to promote adequate strength development.

Safety Precautions:

Wear appropriate PPE and follow the manufacturer’s safety guidelines.

Test and Evaluate:

Conduct mock-ups to assess compatibility and performance.

Document and Monitor:

Keep records of application details and monitor long-term performance.

Consult Manufacturer Guidelines:

Refer to technical data sheets and guidelines for accurate information.

- Familiarize Yourself: Understand product specifications, application methods, and safety guidelines.

- Adequate Training: Ensure proper training for team members on handling, mixing, and application techniques.

- Surface Preparation: Prioritize thoroughly cleaning and repairing structural defects before application.

- Follow Mixing Guidelines: Adhere to recommended ratios and procedures for proper consistency.

- Temperature and Humidity Considerations: Account for ambient conditions during application and curing.

- Efficient Application: Use appropriate tools for uniform application.

- Work in Proper Timeframes: Be mindful of pot life and working time.

- Safety Measures: Provide necessary PPE for team members.

- Quality Control and Testing: Conduct periodic checks and testing for performance evaluation.

- Follow Manufacturer Recommendations: Consult technical data sheets and guidelines for proper use.

By following these recommendations, contractors can ensure effective and efficient use of ERM™ Code 300, leading to high-quality repairs and customer satisfaction.

- Minimum Execution Thickness: Ensure a minimum thickness of 5 mm when applying ERM™ Code 300. This will ensure proper bonding and durability of the repair.

- Maximum Thickness of Execution: Do not exceed a thickness of 50 mm when applying ERM™ Code 300. Beyond this limit, it may affect the curing process and performance of the mortar.

- Temperature Considerations: Avoid using ERM™ Code 300 at temperatures below 5 degrees Celsius. Lower temperatures can impact the curing process and overall performance of the mortar.

- Avoid Dilution with Solvent: Do not dilute ERM™ Code 300 with solvent. Dilution can lead to a decrease in the mortar’s resistance and compromise the effectiveness of the repair.

- Substrate Concrete Age: Ensure that the substrate concrete has an age between 21 and 28 days before applying ERM™ Code 300. The exact duration depends on the curing and drying conditions of the concrete. This allows for sufficient strength development and ensures optimal bonding between the substrate and the repair mortar.

By following these application instructions, you can achieve optimal results when working with ERM™ Code 300.

- Adherence to Manufacturer’s Guidelines: Follow instructions provided by the manufacturer.

- Material Inspection: Check for damage, contamination, and expiration of ERM™ Code 300.

- Mixing Process: Follow recommended ratios and procedures for uniform consistency.

- Application Thickness: Monitor and measure the thickness of applied ERM™ Code 300.

- Adhesion Test: Conduct tests to evaluate bond strength between repaired surface and ERM™ Code 300.

- Curing and Drying: Monitor ambient conditions for proper curing.

- Strength Testing: Perform mechanical tests to assess the mortar’s strength.

- Visual Inspection: Regularly inspect for defects or inconsistencies.

- Documentation: Maintain records of quality control procedures and results.

- Continuous Improvement: Identify areas for improvement and implement necessary measures.

By following this quality control guide, contractors can ensure the effective application and performance of ERM™ Code 300, resulting in reliable repairs and client satisfaction.

technical documents

Photo Gallery

Technical documentation request

Be the first to review “Three-component Epoxy Repair Mortar”